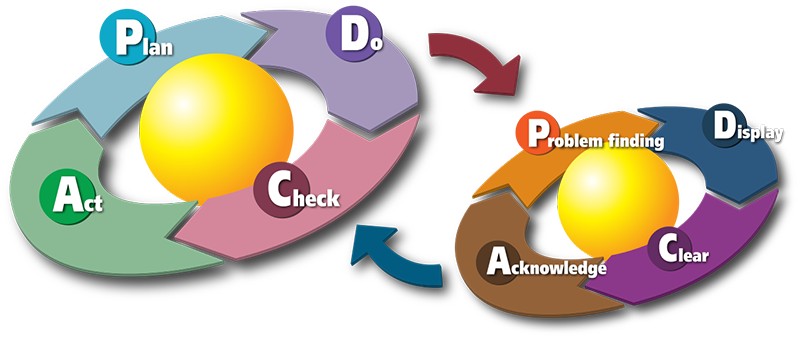

Quality Driven

West Coast Foundry conforms to the requirements of internal and external customers to ensure customer satisfaction. We continually improve the effectiveness of our production processes and quality management system by pursuing four core values and quality objectives:

- Safety: Sustaining a safe working environment for all is our first priority

- Quality: Lead a quality-driven operation to realize internal scrap and customer rejects less than 5%

- Delivery: Achieve an on-time performance of 85% or greater with all WCF Customers

- Value: Encourage value-added processes to reduce costs for WCF and our customers

To ensure our products meet your specifications, we have a number of inspection services.

Our procedures and processes are certified to ISO 9001:2015

Many of our products are certified to strict Nuclear Specifications:

Foundry NCA 3800 (click for cert)

Foundry NCA 10CFR50 Appendix B

Foundry NCA 10CFR21

Inspection Services

The West Coast Foundry team certifies our products to customer specifications following close inspection.

The following are our inspection services:

- Chemical & Physical Testing

- Brinell Hardness

- Charpy Impact

- Tensile Testing

- Dimensional

- Non-Destructive Exam

- Radiographic

- Liquid Penetrant

- Magnetic Particle

- Ultrasonic

- Positive Material Identification (PMI)

- Hydro-testing

- Our procedures and processes are certified to ISO 9001:2015

- Many of our products are certified to strict Nuclear Specifications (NCA 3800, 10CFR50 Appendix B and 10CFR21).